More Connections. Less Cost.

Super-miniaturized and high-density feedthroughs that are reliable, affordable, and robust.

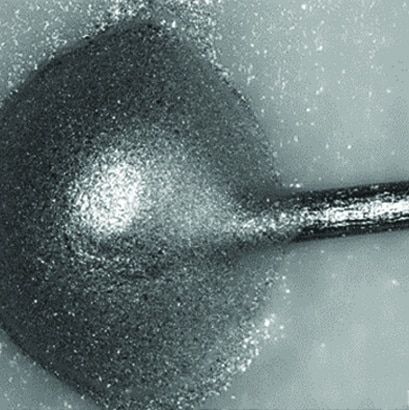

CerMet is an innovative, bio-compatible material system made from aluminum oxide and platinum. This remarkable material technology results in increased channel counts and reductions in feedthrough size and production costs.

Open the Possibilities of Innovation

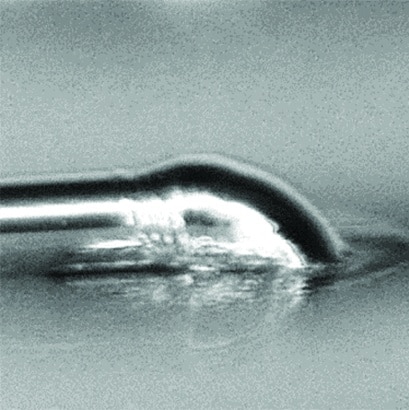

Feedthroughs with more channels (or vias) play a vital role in neurostimulation device innovation by establishing more connections with neural pathways. Smaller feedthroughs mean smaller devices used in minimally inasive surgery. Increased automation in production reduces costs for device makers, doctors and patients.

Whatever your goal may be, CerMet provides companies with the freedom to innovate.

Origins

CerMet composite was developed in the labs of Heraeus Medical Components. Today, SCT Ceramics leverages their expertise in developing and industrializing hermetic, implantable feedthroughs to propose next generation feedthroughs using this remarkable material technology.

Benefits

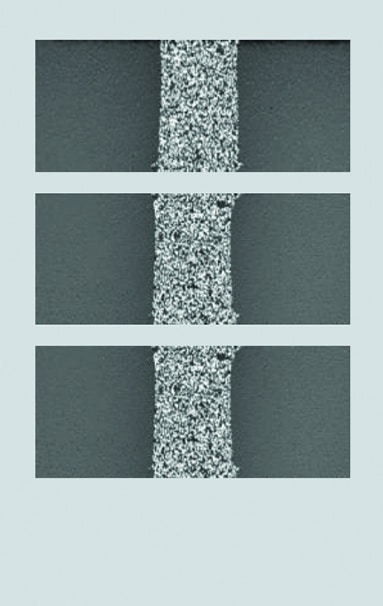

Up to 800 channels/cm2

More channels equals greater precision. For neurostimulation devices, this means that more impulses can be conveyed from the implant to the corresponding receptor. This results in significantly smaller devices and more efficient treatments.

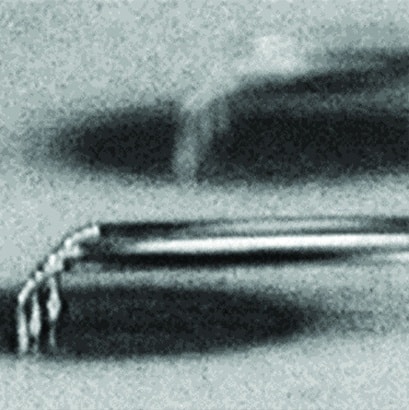

Layered Manufacturing

Ultra reliable patented process results in consistent hermeticity [≤1,0×10^(-9) mbar.l/s.]

Super Miniaturized Feedthroughs

Reduce pitch by more than 50% compared to traditional technology

-Accelerate miniaturization goals

-Increase channel density

Ready to Innovate Your Device?