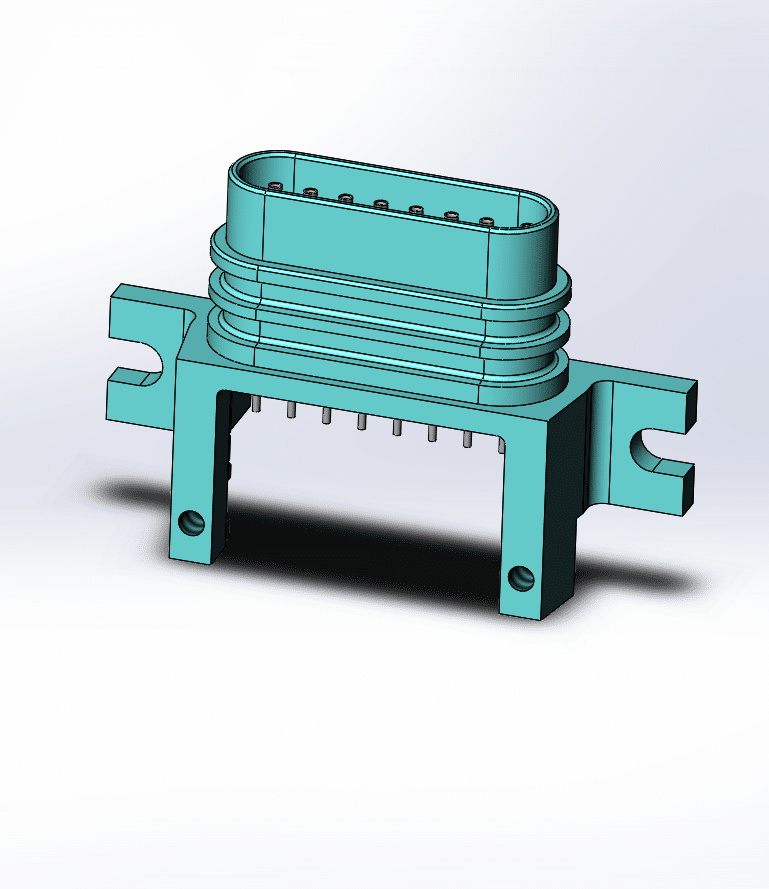

Robust assemblies for high-reliability markets

Our customers come to us to provide solutions that adapt to and compliment their products and capabilities. We rely on applied sciences to develop solutions that are oriented towards function and performance. All of our custom ceramic-to-metal assemblies meet or exceed the technical and quality requirements for their respective high tech applications.

Upon initial evaluation of a client’s project, we identify and elevate the most important criteria. Our Design Verification process ensures product performance and integrity, while taking into account design simplification and cost management.

360 development partners

SCT adheres to the principles of quality, safety, cost and speed throughout the product development cycle.

Our engineering account managers adopt a holistic and strategic approach, which places each client’s needs at the center of every new project. This method allows us to integrate the technical, financial and reglementary aspects of development, all while reducing leadtimes. Every new design is backed by a 360 plan that includes :

- Cost estimates and forecasts

- Functional Prototypes

- Thorough Risk Analysis

- Qualification steps relative to each market

- Quality inspections to meet all regulation requirements

- Cost and leadtime projections for series production

Production Cycle: Advanced Ceramic-to-metal brazing

Miniaturized feedthrough for medical applications

Need help creating specifications?

We know that not every customer has the capability to define all their product specifications – and that’s where we come in. Through collaboration and co-engineering, we can define the technical requirements needed to fit your final product, while working in lockstep with your timelines.

Reliability from A to Z

Our ceramic-to-metal brazed assemblies operate in some of the most demanding conditions in the world. Reliability reigns, whether it’s on the bottom of the sea or inside the human heart. Our qualification and industrialization steps are built for each of our high-reliability markets. We work with clients ranging in size and scope and provide services according to their needs. We provide qualification pieces and can also outline parameters that will ensure a fully qualified and reproducible product.

Looking for a partner with an action plan ? Contact us for more information